First Prover

Accepts dough pieces from the conical rounder and relaxes them prior to final molding

Compact unit gives high output from a flexible layout

The first prover accepts dough pieces from the conical rounder and relaxes them prior to final molding, preserving shape in a controlled, hygienic environment. Removing stress from the dough ensures that it can be molded without tearing and will prove and bake evenly.

- Overview

- Design Options

- Gallery

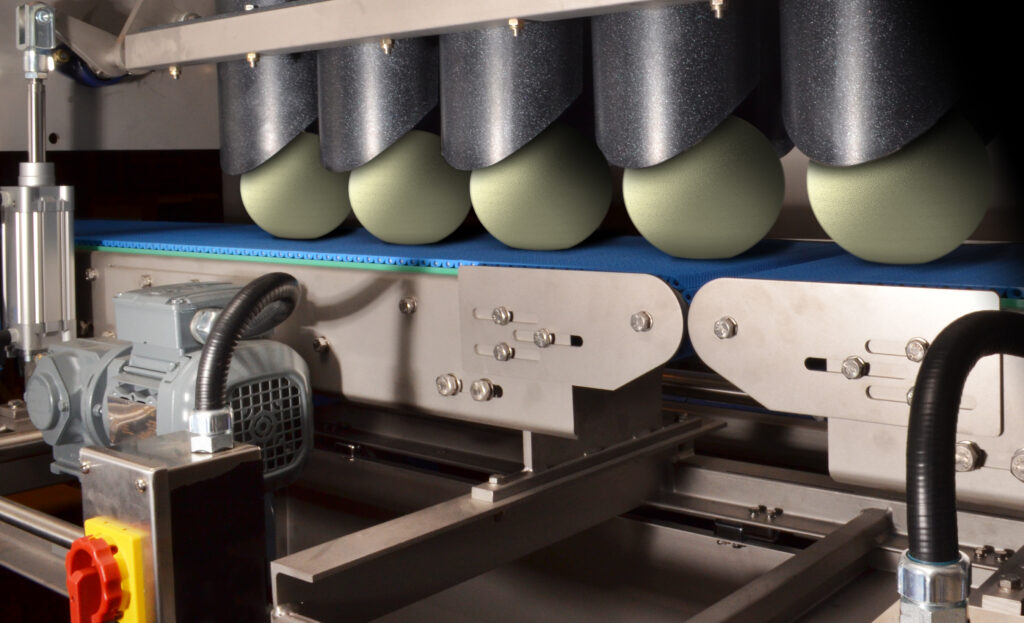

The First Prover accepts dough pieces from the Conical Rounder and relaxes them prior to final molding. Removing stress from the dough ensures that it can be molded without tearing and will prove and bake evenly. Using a First Prover enables the resting to be carried out in a controlled, hygienic environment that preserves the rounded shape and provides a well-controlled feed to the molders. The unit is compact, hygienic and easy to maintain from floor level.

Efficient infeed preserves shape and avoids doubles

Dough pieces are carried through the prover in swing trays that are divided into individual pockets to keep them separate. They are guided into the pockets by a synchronized loading system that ensures there are no gaps and no doubles. The pockets maintain the dough piece shape for presentation to the molder.

Controlled environment and hygienic operation

The enclosed system maintains the dough in optimum condition. The easily removable pockets are metal detectable and made from a washable plastic mesh that facilitates clean and reliable discharge. An air blower dries the parts in contact with the dough to prevent sticking and an extractor fan reduces humidity build-up.

Compact unit gives high output from a flexible layout

Output from a single prover can range up to 9,200 pieces per hour. The machine can be configured to suit any bakery layout, and the small footprint uses minimal floor space. Discharge may be arranged on either or both sides to suit the bakery layout.

- Number of trays: 50, 60 or 100

- Pockets per tray: 8

- Maximum output: 9,200 pieces per hour

- Proof time range: 1 to 30 mins

- Dough piece weight: 200 to 1,100g

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.