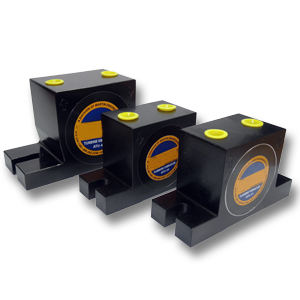

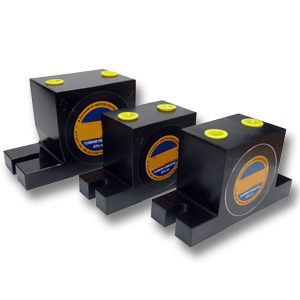

ATU Turbine Vibrators

Simple yet effective vibration generator to help promote product flow

The Series ATU Pneumatic Turbine Vibrators provides a quick solution to a wide range of solids discharge problems.

Fitted externally to hoppers, bins or silos the high frequency vibration is transmitted through the hopper wall into the product promoting flow.

Ideal for internal plant environments, where a low noise solution is required.

Construction:

- Durable anodized aluminum housing or painted

Features:

- Satisfies a multitude of applications

- Available in a wide range of sizes

- Small and compact

- Light weight construction

- Operates in any mounting position

- Temperature rating of -40°C to +176°Cr

- Overview

- Design Options

- Gallery

Applications

The Series ATU Pneumatic Turbine Vibrators have numerous applications within the Food, Chemical, Foundry and Plastic processing industries. They include use in:

- Bins or Hoppers with vertical sides

- Conical Bins and Hoppers

- Rectangular Bins and Hoppers

- Parabolic Bins or Hoppers

- Inclined Chutes

Benefits:

- Low cost

- No lubrication required

- Instant start and stop

- Excellent power to weight ratio

- Interchangeable with similar competitor products

- Lower air consumption than comparable air vibrators

- Operates on air pressures up to 6 bar

- Force and frequency are adjustable proportionate to air supply pressure

- Virtually indestructible – more value for your investment

- Noise levels well below OSHA standard

- Range of sizes to suit a wide variety of application and loading

- Exhaust Air muffler

- Solenoid control air valve with integral timer

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.