Biscuits, cookies & crackers

Streamlined production from end-to-end

Turnkey solutions for biscuit, cookie and cracker manufacturing

We can provide complete, highly automated process solutions for:

- Cookies, both ready-to-eat and frozen dough for later baking

- Hard and soft biscuits

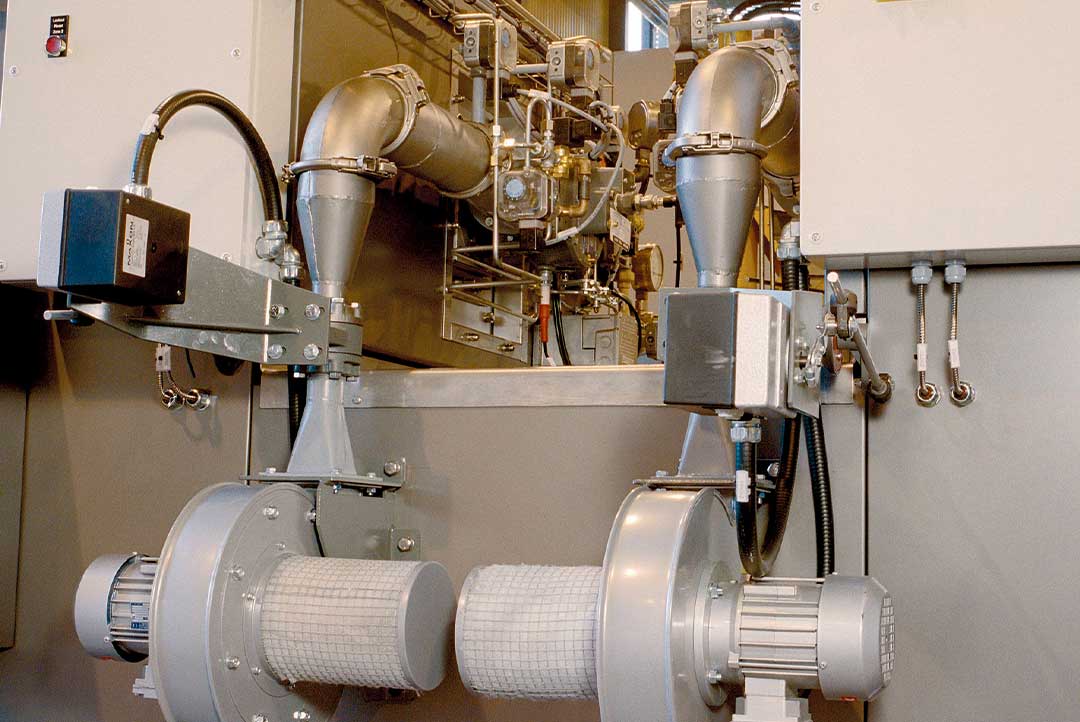

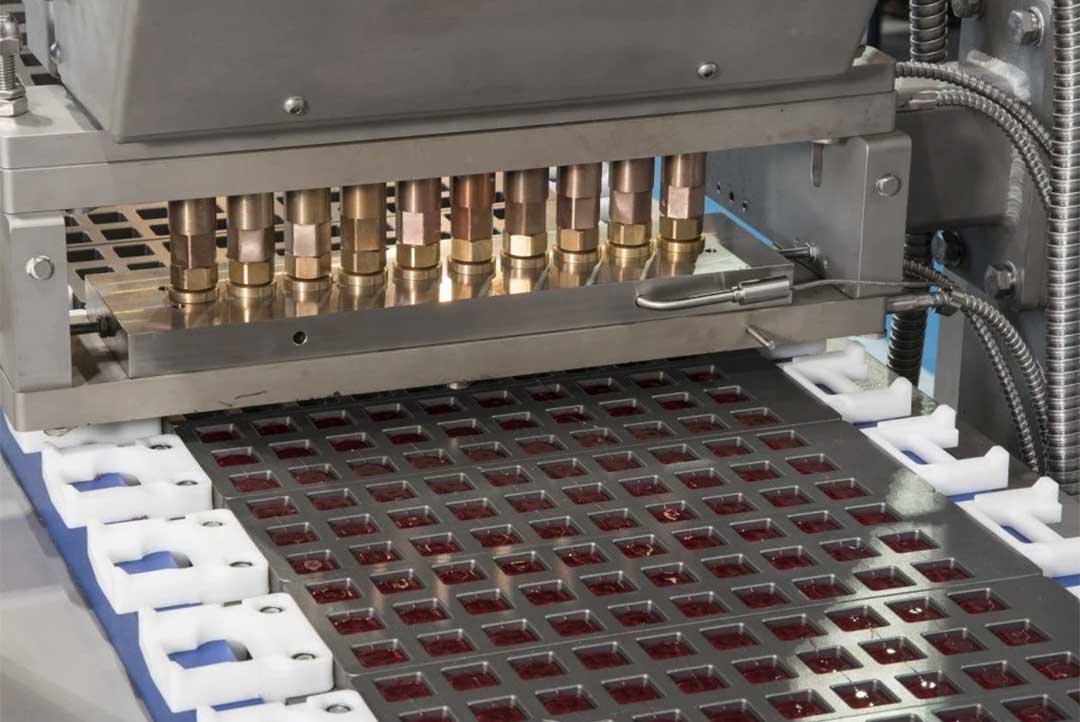

- Sheeted, formed or laminated cookies and crackers

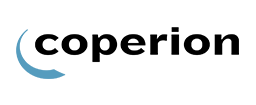

We provide all the technology you need, from pneumatic conveying to mixing, feeding, extrusion, die forming, wire cutting and baking or freezing—and tie it all together into a seamlessly integrated production line with a unified control system that minimizes the need for human intervention.

Design for versatility, efficiency and longevity

We can deliver solutions at any scale, from small R&D and lab production to test new products to large-scale continuous production lines. We also offer custom manufacturing capabilities and have a hands-on approach to integration that leverages our deep engineering expertise to best advantage.

The built-in ability to quickly change recipes and tailor product parameters without making extensive changes to equipment configuration or setup makes our solutions both cost-effective and highly efficient. You’re able to introduce new products or respond to changing consumer demand with speed and agility.

Our technology is built for long-term reliability and maintainability to ensure that your solution continues to perform for years to come. Many of our products have been in use for decades, and we continue to fully support them. We also work with you to take advantage of new innovations as they are introduced, helping to future-proof your solution.

The Coperion difference

Unmatched industry experience

We’ve been providing process solutions for cookie and cracker manufacturing for more than 100 years.

Collaborative expertise

Our engineers work closely with you to develop, test and implement the optimal process solution for your needs.

Test & Innovation Centers

We can build working proof-of-concept demonstrations and laboratory-scale solutions to ensure that your process will perform exactly as expected.

Related Solutions

Get in touch

We take a distinctive approach to the processes that drive manufacturing. Let us know how we can help you achieve your goals for efficiency, productivity and safety.