success stories

Kemutec – generating efficiencies for the bakery industry

Share

Kemutec provides quality and safety in baking applications through sifting solutions

The baking industry is valued at around £3.9 billion in the UK and is one of the largest sectors in the food industry. Bakeries consistently strive to provide their customers with the freshest and highest quality product. Bakers with large-scale plants make up 85% of the market, and as one of the more established industries, they have tried and tested methods to produce the best quality bread, cakes and rolls.

With many plants running at a high level of productivity for a number of years, some sifters in their production line may have become worn and no longer performing as efficiently. As a leading global provider, Kemutec has developed its KEK Sifters to optimize bakery processes, ensuring safety and quality.

Many older sifters in the baking industry will not have the required compliance certification, which safeguards products from recall, protecting employees, customers and consumers. Kemutec’s extensive range of sifters are adaptable to any bakery production line and are ATEX type certified EU Food Compliant (EC) No 1935/2004.

Range of sifters offers adaptable solution

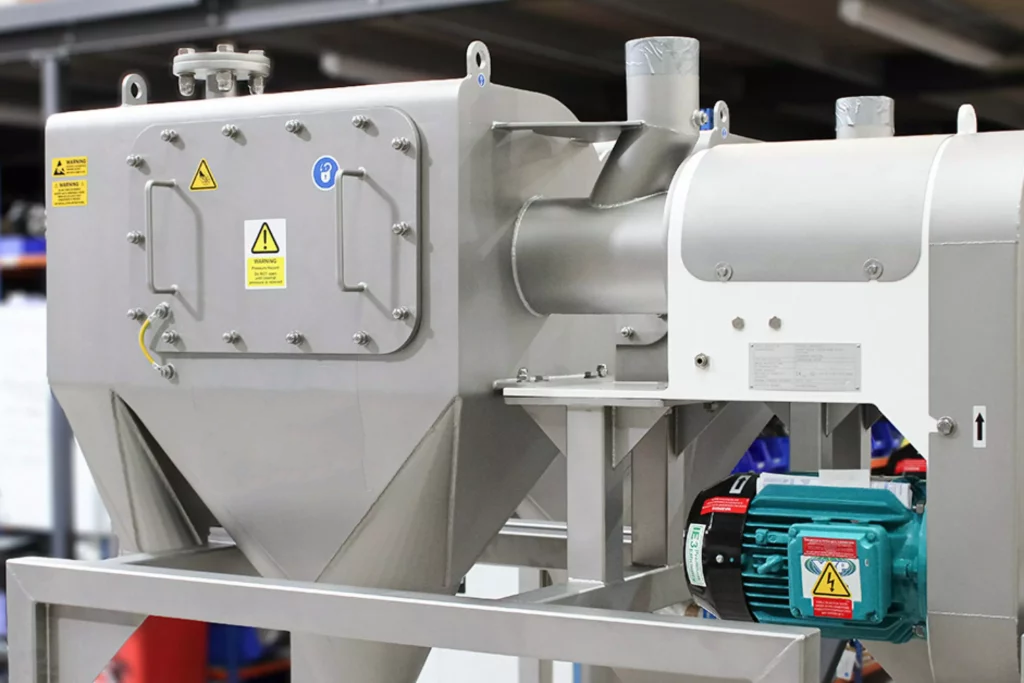

Kemutec KEK Sifters come in seven sizes up to the K1350 at 7.5kW and 100T/hr, which suit various materials and are adjustable to fit an established production line. Kemutec can fit each solution with a different screen: nylon, woven wire, wedge wire and perforated plate.

Commonly, sifters work under gravity conditions; however, Kemutec has a range of pressure & vacuum rated sifters specifically designed for use within both vacuum and over-pressure pneumatic conveying systems with a working pressure of +/- 0.7 barg (10 psi).

Kemutec’s sifting solutions are hygienic, compact, adaptable, low maintenance, and accessible through a cantilever shaft system, allowing full access at one end for maintenance and cleaning. The KEK Sifters are fully sealed with the option to perform in a pressurized line. Their multi-faceted benefits make the range an ideal solution to improve and maximize a bakery process.

Guarantee safety while maintaining quality

Safety is of the utmost concern within the baking industry, but unfortunately, unidentified objects can sometimes enter the process. Contaminants can range from nuts, bolts, screws, insects, ties, strings, and large agglomerates, which can go into the system at several points along the process line. By using Kemutec’s KEK Sifters at various critical control points, such as at silo distribution lines, after milling systems, or before packaging lines, customers can ensure their product is safe and without any contaminants.

Bakeries receive their ingredients from a range of sources, and they must ensure this product is of the correct quality before introducing it to their recipe; they must guarantee that their final product is protected without contaminants when it reaches their customers. Kemutec KEK Sifters are effective policing sieves that ensure no harmful contaminants make it into the final product. KEK Sifters have a variety of uses, such as for light de-agglomeration or pre-breaking of light agglomerates and flakes.

Having a sifter that allows bakeries to produce high-quality products while maintaining safety standards makes Kemutec an ideal partner for those looking to upgrade their bakery processes in line with current regulations.

Compliance certification guaranteed

By developing the most advanced technology, Kemutec consistently aims to deliver customers high quality and safe solutions. Part of that service is following compliance certification and ensuring that all their sifters are ATEX type certified for Zone 20 internally & 21 Externally and EU Food Compliant (EC) No 1935/2004. Kemutec operates at ISO 9001, 14001.

Kemutec strives to enhance the working efficiency of these critical control points within any bakery system. It is typical when processing thousands of tons of powder per day, to lose anywhere between 0.01% and 1% of material through inefficient sieving processes.

Practical Example

Running 3,000kg/hour rates @ £1.50/kg – flour during a 24 hour day

1% efficiency loss = 720kg/day = £1,080 per day

0.01% efficiency loss = 7.2kg/day = £10.80 per day

An efficient sieving process can quite clearly save operational time, product and considerable cost. Kemutec have the relevant expertise, and history needed to enhance the efficiency of existing processes and reduce their waste while continuing to deliver the best quality product.

Bakers face many challenges as part of their production processes but by investing in sieving solution that delivers improved efficiencies, a bakery can improve operator safety, reduce costly waste, and maximize its throughput. Handling multiple ingredients and safe-guarding end-product from contaminants is also made possible through Kemutec’s sifting technologies; providing producers with the peace of mind that critical point checks are automated, and that the quality of their product is maintained to the highest level.

Related articles

Stay connected

Subscribe to keep up to date with current perspectives, events, white papers and more.