New Baker Perkins Cooling Conveyor improves productivity for Powder Coating manufacturers

Share

Schenck Process FPM became Coperion on August 1, 2024. This release predates that name change.

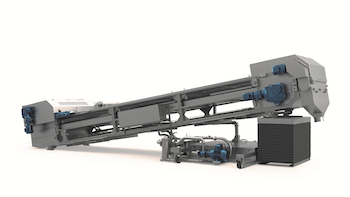

The new stainless-steel belt cooling conveyors are designed to match the outputs of the company’s MPX and HPX series of industrial twin-screw extruders, which can produce up to 2900 kgs per hour, across the full range of powder coating and toner formulations.

Designed to cool extruded material efficiently and produce flakes that are ideally sized for feeding into the milling stage of the process, the new cooling conveyor integrates seamlessly into the powder coatings production line and helps to maximize end-product quality.

Peterborough, UK, April 24th 2023 – Baker Perkins, a Schenck Process Food and Performance Materials (FPM) company, has launched a new range of cooling conveyors for powder coatings applications. This addition by the renowned supplier of extrusion technologies is key to the availability of turnkey, fully automated powder coating process lines from one trusted source.

Baker Perkins is working in partnership with Schenck Process FPM sister company, powder processing specialist Kemutec, to design, build, and install all the systems required for a complete end-to-end powder coating process: from feeding to extruding and cooling, through to milling, sifting, and screening.

Integrated process systems have a single touchscreen HMI which provides clear, at-a-glance visualization of the whole process with the current status of all major components and parameters to aid decision-making and process optimization.

When the operating parameters of the extruder and cooling conveyor are defined for a specific product, fully automated start-up and shutdown, at the press of just one button, improve the efficiency of the entire process.

Increased production time through effective maintenance is also a significant benefit of choosing systems from Baker Perkins. Integration into the production line’s control system allows automated cleaning of the cooling conveyor, reducing downtime, minimizing the risk of batch cross-contamination, and increasing operator safety.

All cooling conveyors from Baker Perkins feature a built-in flaking unit with its own air vortex cleaning system for dust extraction, which further cuts labor and turnround time whilst ensuring a high-quality product with minimal contamination risk.

Stay connected

Subscribe to keep up to date with current perspectives, events, white papers and more.