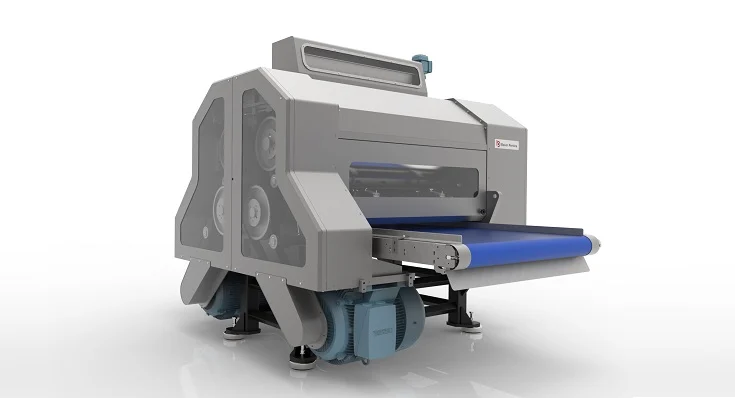

Flake Master Flaking Mill

Provides consistent processing

This unit provides consistent processing of a wide range of flakes including corn, bran and multigrain; traditionally cooked grains and extruded pellets can also be processed.

Accurately controlled process conditions deliver optimum flaking performance, while high efficiency, hygienic design and minimum maintenance contribute to low production costs.

- Overview

- Design Options

- Gallery

Baker Perkins’ FlakeMaster flaking mills deliver consistent high quality flakes at outputs of up to 1,750kg/hr. Accurately controlled process conditions deliver optimum flaking performance, while high efficiency, hygienic design and minimum maintenance contribute to low production costs.

High Quality Flakes

High quality flakes are produced by the constant roll surface temperature, maintained by a high capacity water cooling system. Desired flake thickness is maintained by precise gap control and regulated product infeed across the full width of the roll.

Reduced Ownership, Servicing and Cleaning Costs

Typical life of a flaking roll before regrinding is 10,000 hours, reducing downtime for cleaning and maintenance. Regrinding can be done up to 20 times, giving rolls a maximum operating life of 200,000 hours. Acoustic drive covers and anti-vibration mounts reduce factory noise levels. Open design provides good visibility and easy access for cleaning.

Superior Productivity

Unique oscillating scraper blades maintain uniform contact across the full width of the roll to reduce uneven roll wear and ensure even heat distribution.

Differential roll speeds

Infeed Options:

- Grooved roll – typically for corn grit

- Vibratory infeed – typically for extruded pellets

- Distribution box – typically for whole grain wheat

Discharge Options:

- Reversible discharge conveyor

- Vibratory discharge conveyor

- Vacuum take-off systems with sampling tray

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.